APPLICATION OF THE FILBLAST SHEAR REACTOR IN GOLD LEACHING

The factors controlling cyanidation of gold are •Mixing intensity •Oxygen concentration •Cyanide concentration •Temperature and pressure

By increasing the concentration of dissolved oxygen in the slurry, the mixing intensity and the process pressure, the efficiency of the process is increased. The Filblast Shear Reactor applies all these factors which increase the efficiency of the dissolution and the rate of the extraction of the gold and is due to:

• The high shear rate which keeps the gold surface clean and active.

• The extremely fine oxygen particles generated by the interaction of oxygen and the slurry.

• The high oxygen concentration at the gold surface due to improved oxygen dissolution.

• The high pressure which speeds up chemical activity.

• The reduced thickness of the boundary layer which is formed on the gold surface during cyanidation through which the cyanide and oxygen must diffuse or pass the leach the gold.

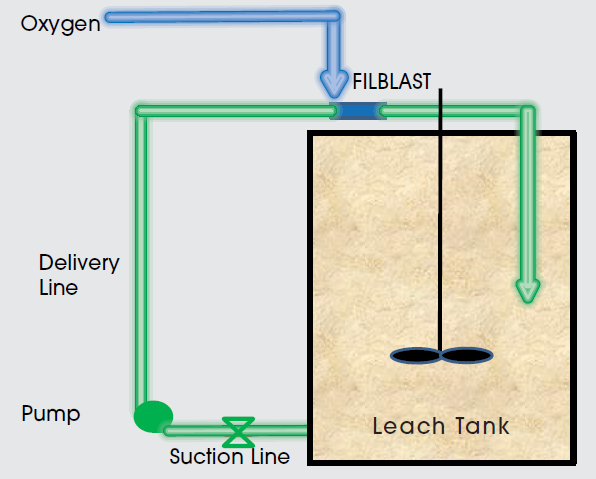

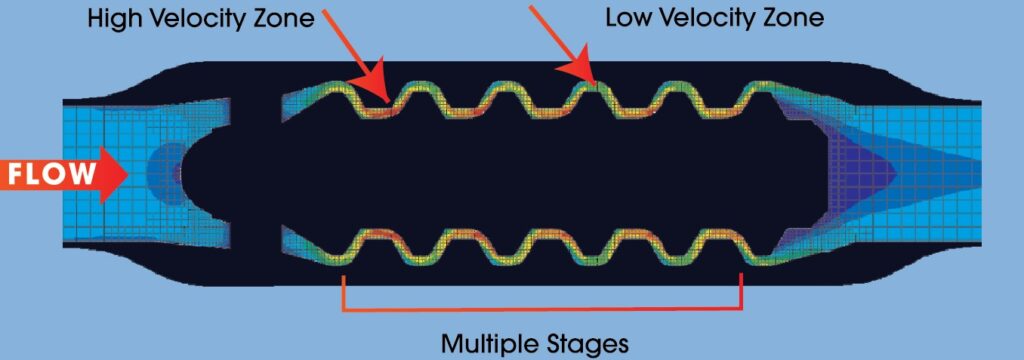

In the Filblast Shear Reactor, the slurry and oxygen is introduced into the reactor inlet chamber at a pressure of around 4.0 to 4.5 bar using a centrifugal pump. The oxygen and slurry follow a winding path as it moves along the length of the reactor.

This high efficiency translates to •Higher gold recovery •Increased leaching rate •Increased dissolved oxygen concentration •Reduced oxygen consumption •Reduced cyanide consumption •Reduced pulp viscosity •Higher throughput •Consistency of results

FILBLAST SHEAR REACTOR CONFIGURATION