APPLICATION OF THE FILBLAST SHEAR REACTOR IN FLOTATION

Since the 1980’s several flotation devices have been on the market that use pipe reactors to generate microbubbles and promote particle-bubble attachment outside the flotation cell itself. Most of these devices exploit venturi effects and use self-aspirating air. The physics behind the operation of the Filblast Shear Reactor is fundamentally different.

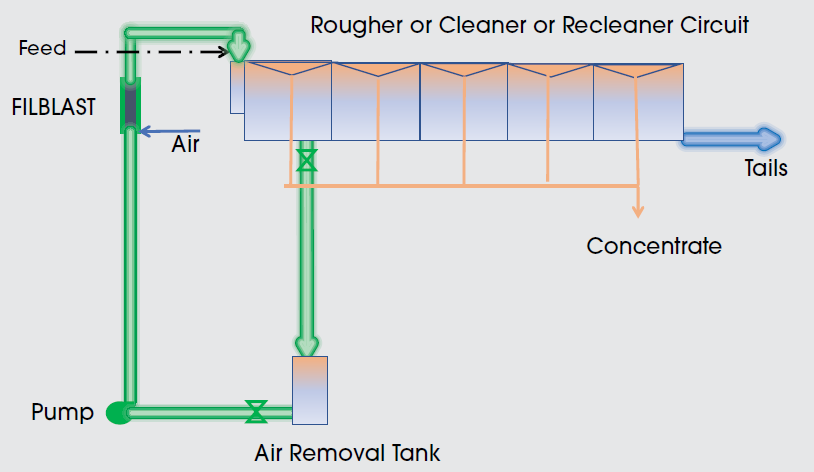

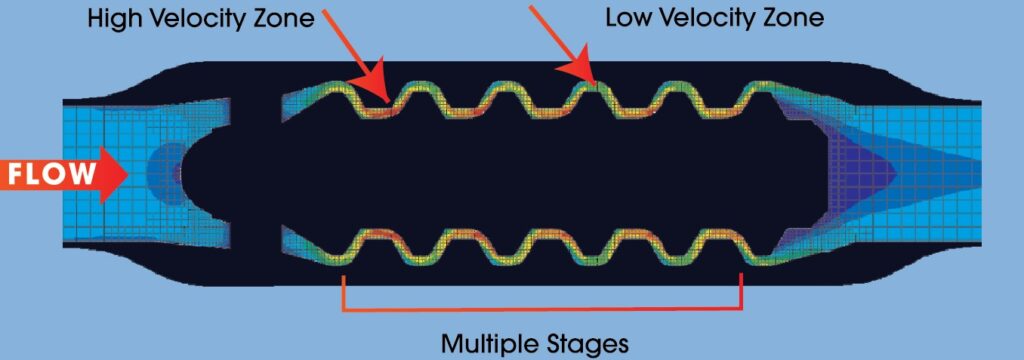

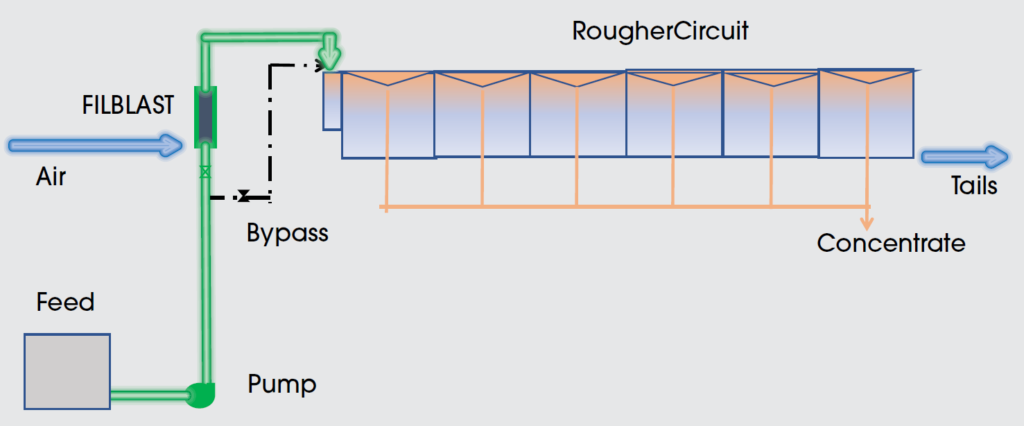

In the Filblast Shear Reactor, the slurry and air are introduced into the reactor inlet chamber at a pressure of around 2.0 to 2.5 bar using a centrifugal pump and compressor. The air and slurry follow a winding path as it moves along the length of the reactor.

The high shear stresses generated in the Filblast, which corresponds to Reynolds numbers of more than 15000 are responsible for the generation of the microbubbles and high velocity mixing. The high shear stresses and mixing are also responsible for the promotion of rapid attachment of the bubbles to the valuable mineral-bearing particles. This is true for liberated ultrafine particles that can bypass the flotation process in conventional mechanical cells, which rely only on an impeller-stator mechanism for bubble generation and bubble -particle attachment.

FILBLAST SHEAR REACTOR CONFIGURATIONS

FILBLAST SHEAR REACTOR CONFIGURATIONS